- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-06-10 Origin: Site

In today’s fast-paced manufacturing world, efficiency is key. But how can businesses meet complex production demands without compromising on quality? This is where turnkey machining solutions come in.

A turnkey machining solution provides a fully integrated system that’s ready to go from day one. In this post, we’ll explore what turnkey machining solutions are, their key benefits, and how they can streamline your manufacturing process.

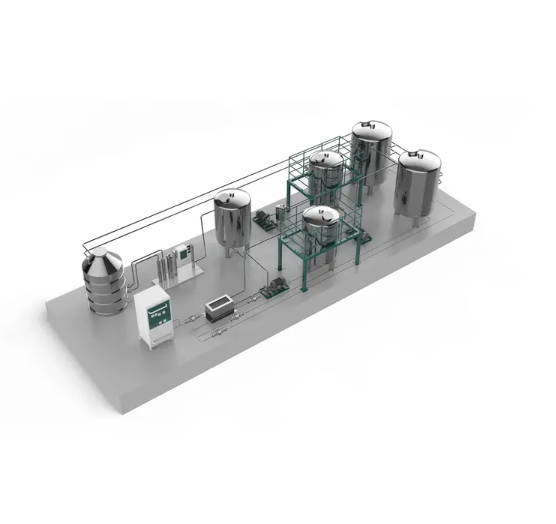

A turnkey machining solution is a fully functional, ready-to-use system designed for specific machining tasks. It integrates every component necessary for production, including software, mechanical systems, and quality control processes. This approach ensures that when the system is delivered, it is ready for immediate operation, reducing setup times and complexities.

Unlike traditional machining setups, where various machines and components are sourced separately, turnkey solutions provide everything in one package. This eliminates the need for additional assembly or configuration, saving valuable time. In traditional setups, each machine may require its own setup, calibration, and testing, often leading to inconsistencies and delays.

Turnkey solutions are designed to be seamless, offering a single point of responsibility for the entire process, from design to implementation. This unified approach helps streamline operations, improve efficiency, and reduce the potential for errors compared to piecemeal systems.

Turnkey machining solutions come fully integrated and tested, ensuring they're ready to use immediately upon installation. Pre-delivery testing is crucial as it ensures the system meets all performance specifications, minimizing risks of downtime. This testing guarantees that the system functions smoothly from day one, helping businesses avoid costly operational delays and ensuring high production efficiency.

One of the main advantages of turnkey machining solutions is their custom-engineered flexibility. These systems can be tailored to meet specific production needs, such as handling unique materials or intricate part designs. Industries like aerospace and medical devices require these customizations to meet complex production requirements and high precision standards. Custom flexibility ensures that your system can evolve to meet changing demands without needing a complete overhaul.

Turnkey machining solutions are equipped with in-line testing and inspection systems to maintain high product quality. These systems continuously monitor the manufacturing process to ensure consistency and prevent defects. Industries that require strict quality control, like medical device production or aerospace, benefit from these built-in features. Continuous quality assurance helps businesses comply with industry standards and minimize the risk of costly rework or product recalls.

Turnkey machining solutions significantly reduce setup time by providing pre-integrated systems. This means you don’t have to worry about on-site engineering, which can delay production. The quick installation of turnkey systems cuts down on downtime, leading to immediate productivity gains. The streamlined approach results in fewer interruptions and quicker time to market, helping you save on long-term operational costs.

One of the main advantages of turnkey machining solutions is having a single point of contact for the entire project. This reduces complexity, as there’s no need to manage multiple vendors. You also get streamlined communication, which means faster problem resolution and fewer delays. Having a dedicated partner ensures your project stays on track without the hassle of juggling different suppliers.

Turnkey machining solutions automate many tasks, which boosts throughput and reduces the likelihood of human error. With precision systems in place, cycle times are optimized, leading to improved overall productivity. These solutions are designed to run efficiently, even in high-demand environments, enhancing performance and helping businesses maintain a competitive edge.

CNC (Computer Numerical Control) machines play a pivotal role in turnkey machining solutions, especially for precision manufacturing. These machines use pre-programmed software to control machine tools, ensuring accuracy and repeatability. CNC systems can automate complex processes like milling, drilling, and turning. This level of automation reduces human error and improves consistency in mass production, making it ideal for industries requiring high precision, like aerospace and automotive.

Robotic arms and automated systems have revolutionized production lines. These systems handle tasks such as part handling, assembly, and inspection with high speed and accuracy. Robotic automation significantly enhances production capabilities, allowing manufacturers to increase throughput while reducing labor costs. Additionally, robots can work continuously, ensuring 24/7 productivity and minimizing downtime. Their ability to perform repetitive tasks without fatigue makes them ideal for high-volume manufacturing environments.

Some industries require specialized turnkey machining solutions, tailored to their unique production needs. For example, semiconductor manufacturing demands extremely precise and clean environments, while medical device production needs compliance with strict regulatory standards. Custom-built systems for these sectors are designed to meet specific requirements, including unique materials, temperature controls, or environmental conditions. These solutions are often developed after careful analysis of the production process and ensure that the equipment meets the high standards demanded by specialized industries.

Start by evaluating the specific requirements of your production process. Consider factors such as part complexity, production volume, and required precision. If you need to produce intricate parts, look for a solution that can handle high precision. For high-volume production, ensure the system can manage large quantities efficiently. Identifying these needs will help you determine the appropriate features and capabilities for your turnkey machining solution.

When selecting a turnkey machining partner, consider their experience, capability, and industry specialization. Look for a provider with a proven track record in your specific industry. Also, assess the support they offer after installation. A good turnkey partner should provide ongoing maintenance, training, and troubleshooting services to ensure your system operates at peak performance.

Calculating ROI is essential when investing in a turnkey machining solution. Consider how the system will reduce operational costs, improve efficiency, and shorten your time to market. A solution that boosts productivity and minimizes downtime will pay off in the long run, justifying the initial investment. Be sure to factor in both short-term savings and long-term gains when evaluating the overall return.

In the aerospace industry, precision is everything. Turnkey machining solutions are crucial for manufacturing high-precision aerospace components. These parts must meet rigorous quality standards to ensure safety and performance. Turnkey systems provide the required accuracy and consistency while optimizing production time and reducing errors, making them essential for the aerospace sector.

Turnkey machining solutions are ideal for the medical device industry due to their ability to meet strict regulatory requirements. These solutions ensure the cleanliness, quality, and traceability of parts, which are critical in medical manufacturing. From surgical instruments to implants, turnkey systems help maintain high standards of hygiene and precision, complying with FDA and other regulatory bodies.

For the automotive and electronics industries, turnkey machining is invaluable in maintaining high-volume production and ensuring product quality. These sectors demand efficient systems that produce parts with minimal variation. Turnkey solutions help streamline production lines, improve consistency, and meet the fast-paced demands of these industries while maintaining strict quality control standards.

The semiconductor industry relies on complex and delicate production processes, which are well-supported by turnkey machining solutions. These solutions ensure the precise manufacturing of semiconductor components while maintaining high-quality standards and reducing errors. Turnkey systems provide the flexibility and precision needed to meet the demands of this high-tech industry, ensuring efficient production and minimal downtime.

Traditional machining often requires separate equipment, tools, and suppliers for each step of production. This can lead to complexities, with multiple parties involved in sourcing, assembly, and delivery. In contrast, turnkey machining solutions offer a single-source approach. A turnkey provider handles everything from design to final production, ensuring smoother project management and reducing potential delays or miscommunications.

Turnkey machining systems are designed to be production-ready from the start. With integrated systems, they reduce setup times significantly compared to traditional methods. In traditional machining, each step might require separate setups or adjustments. Turnkey systems streamline the process, enabling faster time-to-market with fewer delays and less downtime.

While turnkey machining solutions often require a higher upfront investment, they offer long-term savings. Traditional methods involve costs from managing multiple suppliers, machine maintenance, and logistics. Turnkey solutions consolidate these costs, providing efficiency and lower maintenance expenses over time. The reduction in labor costs and increased production uptime make turnkey solutions a cost-effective choice in the long run.

One of the biggest hurdles when adopting turnkey machining solutions is the higher upfront cost. Compared to piecemeal solutions, turnkey systems require a larger initial investment due to the comprehensive equipment, software, and design services included. However, these higher initial costs can be justified by the long-term benefits. Once implemented, turnkey solutions provide increased operational efficiency, reduced downtime, and lower ongoing maintenance expenses, making them a worthwhile investment for businesses looking to scale and streamline production.

Turnkey machining solutions often need to be customized to meet specific production requirements, which can be complex. Tailoring a system to handle unique parts or specialized materials requires careful planning, precise engineering, and time for development. While this process may add complexity and potential delays, working closely with an experienced provider can ensure that the system meets all specifications and integrates seamlessly into your production process.

Integrating a turnkey machining solution into an existing production line can present challenges, especially if the current system has legacy equipment or outdated software. Compatibility between the new turnkey system and older machinery is essential for smooth operations. Planning for potential upgrades or adjustments to existing infrastructure may be necessary. However, working with a provider who specializes in turnkey solutions can help identify and address these integration issues, ensuring a seamless transition.

Turnkey machining solutions offer increased efficiency, reduced complexity, and long-term cost savings. These systems streamline production by integrating all components into a single, cohesive solution. For businesses looking to optimize processes and remain competitive, turnkey machining is a smart choice that can lead to improved productivity and lower operating costs.

A: A turnkey machining solution is a fully integrated, ready-to-use system designed to perform specific machining tasks. It includes all necessary components, such as equipment, software, and systems, pre-installed and tested for immediate use, minimizing setup time.

A: Industries like aerospace, medical devices, semiconductor, and automotive benefit from turnkey machining due to the need for precision, high-volume production, and strict quality standards.

A: Consider factors like production volume, complexity of the parts, quality standards, and whether you need customized solutions. If you need to streamline production and reduce setup time, turnkey machining is a great option.